Continuous Flow: how to distribute the work?

How to distribute the work in a continuous flow? After rearranging all the physical processes to implement continuous flow in a cell, it is time to bring the people into it, the operators and the customers. On this part of the process many questions come to mind, like “how many operators in which station?”, “how will the takt time be satisfied?”, and etc. We have the answers and we will present you some techniques below.

First things first: how can you decide the number of operators to meet a certain takt time?

It is important to avoid negotiations between the team because it takes time and it will probably lead to more operators involved than necessary. So, we present here a very efficient equation to solve this question:

Example:

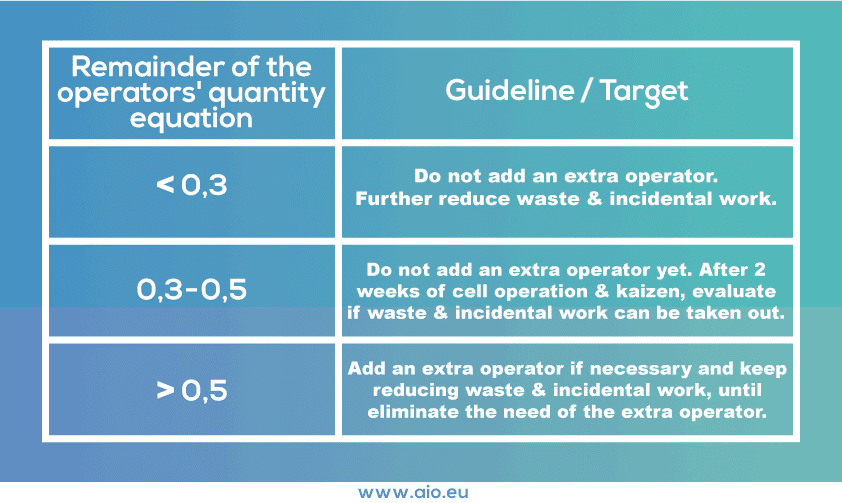

The result is 2.2 operators and you might be wondering if we should use 3 operators in this case. The answer is no. Why? Because 3 operators in a 2.2 equation might result in low productivity and that is not the goal of a continuous flow. We suggest 2. The intention of using only 2 workers here is to make them improve their takt time, so a third one is not required. We have a table to guide you on this decision:

You might be wondering “how to make 2 operators improve and reach the takt time?” Well, motivation is very important in the process. And patience. Managers, engineers and production associates will need around 2-4 weeks to reach their objective. A very engaged team can reach 80% of the goal in the first week, and 90% in the second week. It is very impressive how a full commitment to intense kaizen can improve the takt time. The final 10% is the hardest part, usually it requires all elements of support and production to come together, and when 100% is finally reached, there is a sense of achievement in the team and a new standard was created for the company.

What if my “number of operators” equation result is over -,5?

We just gave an example of what to do when the result of the equation is -,2. Now, we present how to operate when the result of the equation is over -,5; which means you will need an extra operator temporarily in the cell.

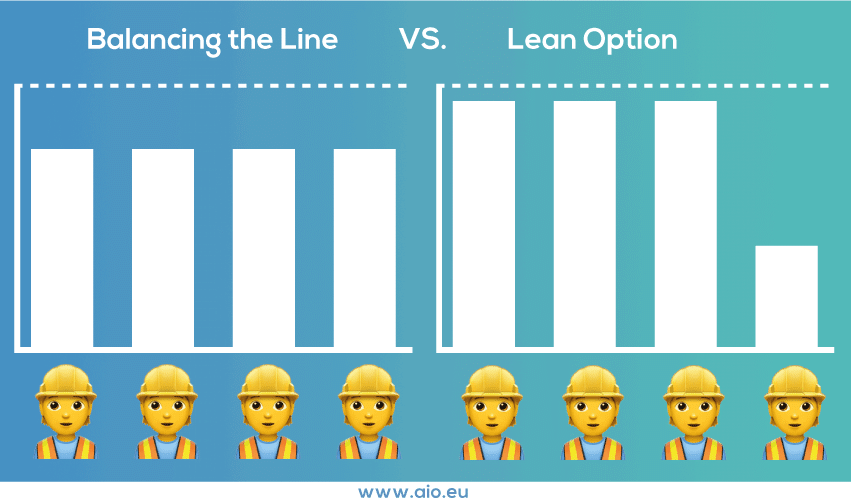

In this case, you will have an extra worker, but we do not recommend “balancing the line” by delegating the same amount of work for each operator. In order to apply kaizen, improve the takt time, and visualize the waste, it is necessary to fully distribute the work between all operators, but one. One of them will have less tasks to do, and this will reveal waste and opportunities of improvement on the operation with the time. This uneven distribution of work will eventually lead to one less operator in the cell and a new standard developed.

How to distribute the work between the operators in a continuous flow?

Now, let’s talk about work distribution. There are several ways to do the work distribution among operators in a cell. Here we present 6 possibilities:

- Split the work between operators, each of them performing one part of the total takt time.

- Create a circuit where one operator does a complete circuit of the cell in direction of the material flow.

- Reverse flow, which consists in doing the circuit in the reverse direction of the material flow.

- Combination of slitting the work and a circuit or a reverse flow.

- One-Operator-per-Station, which consists in literally each operator staying at one workstation.

- The Ratchet, in which each worker operates in two workstations and advances the work-in-progress every time he goes to the downstream station.

We will present each of them very soon. In the meantime, we would love to know your thoughts about the ideas presented. So, do not hesitate to leave a comment with your thoughts!