Takt Time or Cycle Time: what are we talking about ?

The most frequent confusion consists in confusing cycle time and takt time. Cycle time corresponds to the time necessary to carry out an operation whereas the takt time represents the customer’s demand ! Unfortunately, this is the most frequent error, because the 2 notions have two different objectives. Cycle time is associated with delivery times and can be measured with a stopwatch for example… As for Takt Time, it obviously has a positive influence on the logistics of a company! But it must be well used…

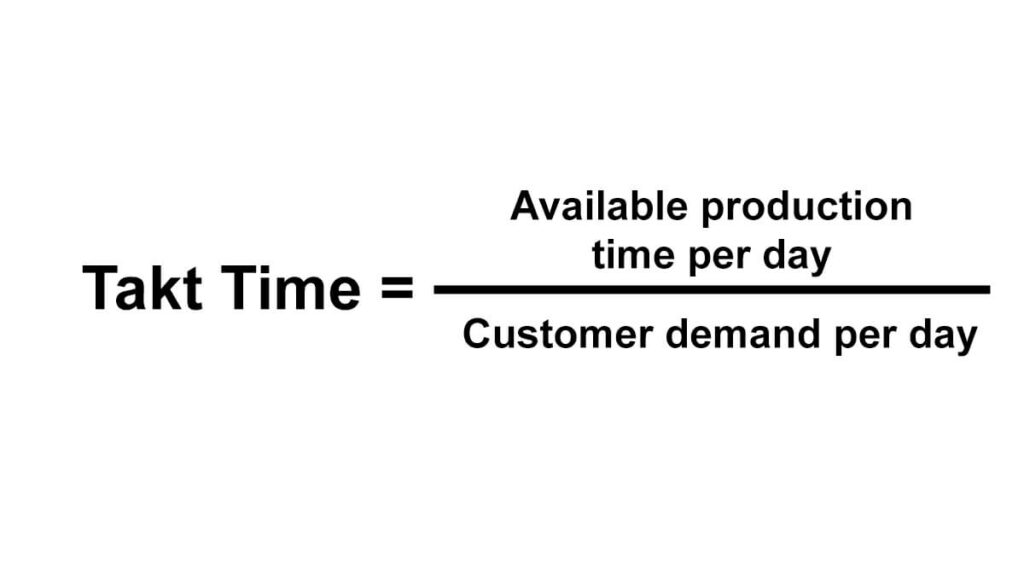

Takt Time

Takt time represents the rate of production necessary to meet customer demand. Indeed, it is the latter that sets the pace !

It is calculated as follows:

Available production time per day / Customer demand per day

Cycle Time

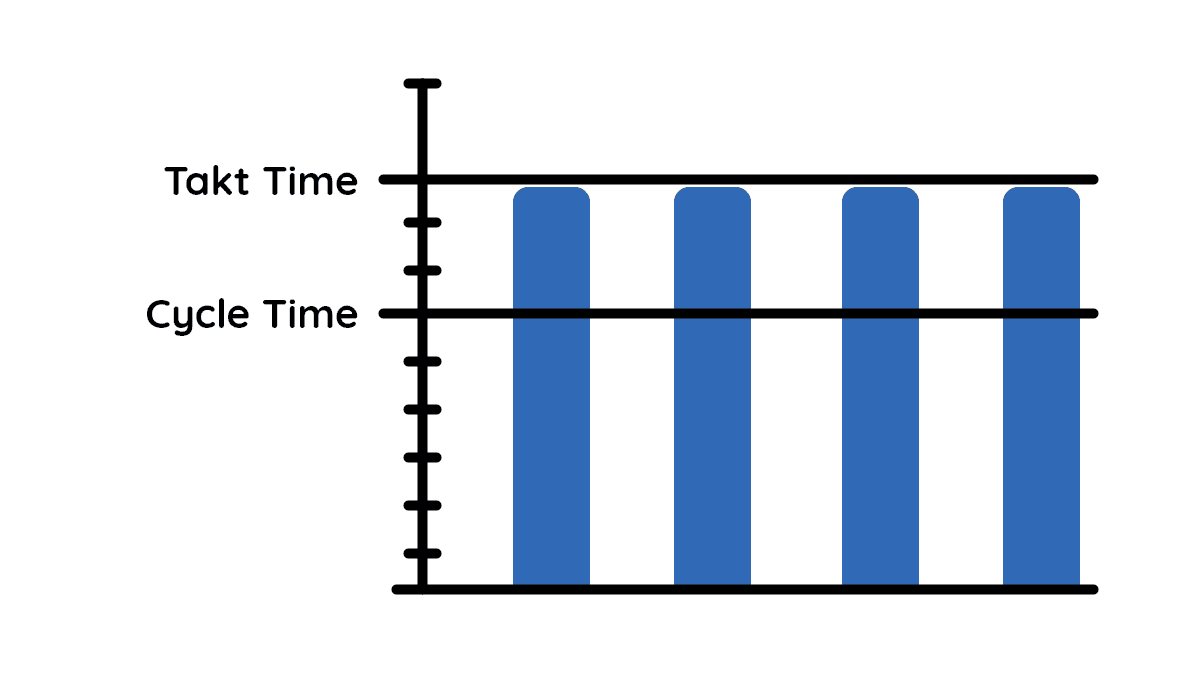

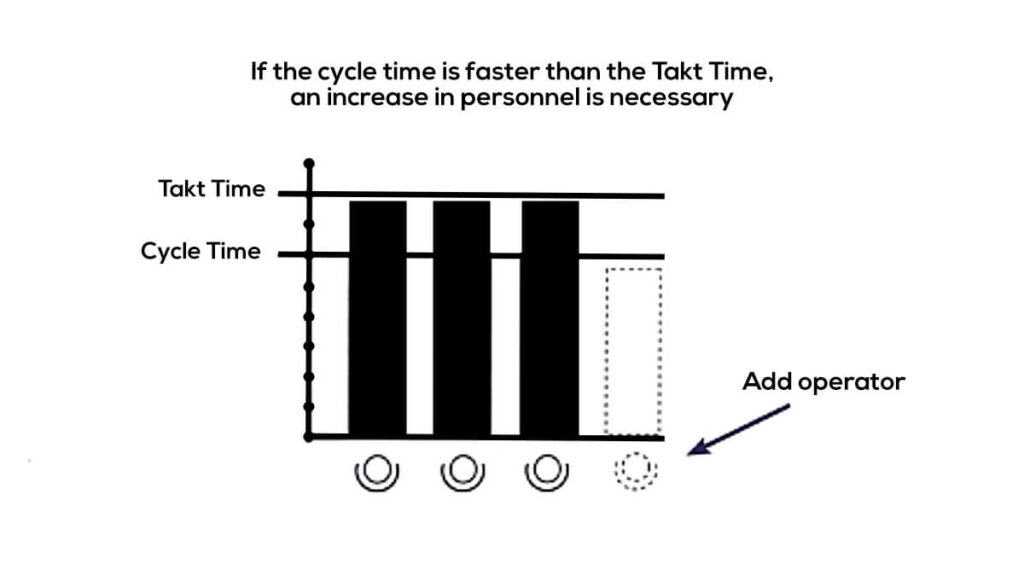

This is the frequency at which a finished product actually leaves the timing cell. We often encounter processes that run at cycle times faster than the Takt time. Production teams need to have a cycle time that is slightly less than the takt time in order to be able to deal with supply shortages or machine failures.

It is important to keep in mind that when the cycle time is shorter than the takt time, the probability of overproduction increases with the potential addition of operators. Production problems are masked, motivation is reduced to find the causes.

Difference between Cycle Time and Takt Time

It’s worth noting the importance of time in any business, whether it’s a manufacturing or service business. Mastering time offers several advantages.

Indeed, it allows to respect delivery deadlines, cost reduction and inventory management, improve productivity and reactivity and customer satisfaction.

The cycle time must be adapted to the customer’s demand but must always be lower than the takt time. It must not reach 100% of the takt time. It can be modified by the production time in order to meet customer demand. This indicator also provides useful information to adjust the execution time.

For takt time, it is often compared to cycle time in order to understand the current state of production capacities. It is an effective way to avoid over or under production. It is also used to improve or restructure production lead times.

Companies that are used to adapting to customer demand, i.e. regularly changing Takt time, have to work on cycle time. They must then take a very detailed interest in the work content of the operators, and generate Kaizen in order not to exceed 95% of the Takt Time.

So think about building a production line, which easily accepts Kaizen and which allows to easily modulate the cycle time!