Inspiration from Toyota Environmental Challenges

Inspiration from Toyota Environmental Challenges

To be honest, manufacturing cars is not an easy thing to do. When you take into account that you need to build a great many cars, in turn this increases needs for resources. One of these is energy none the least, to manufacture the vehicles. However, this also means that you produce CO2 emissions, which isn’t the best thing for the environment. That’s basically what’s been going though Toyota ‘s mind.

Clean manufacturing

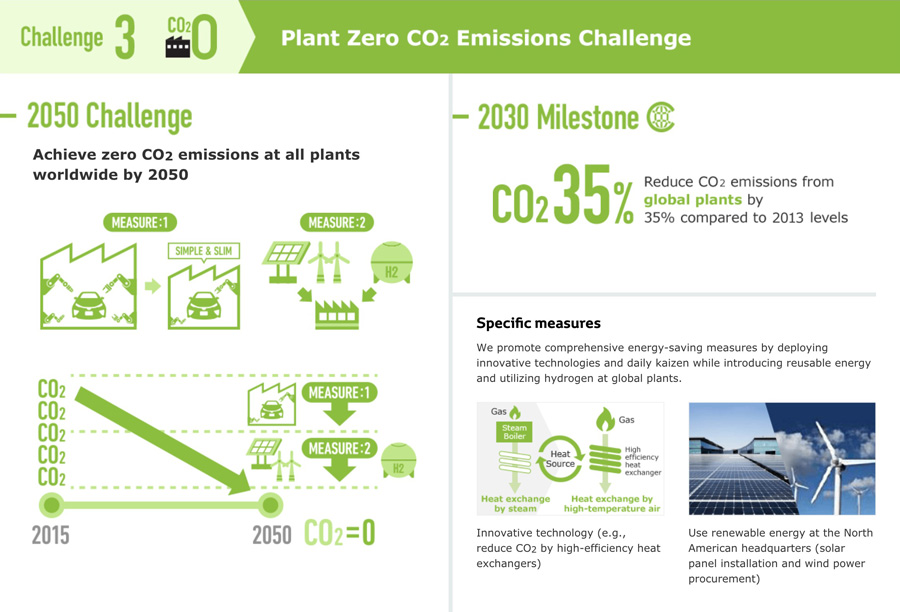

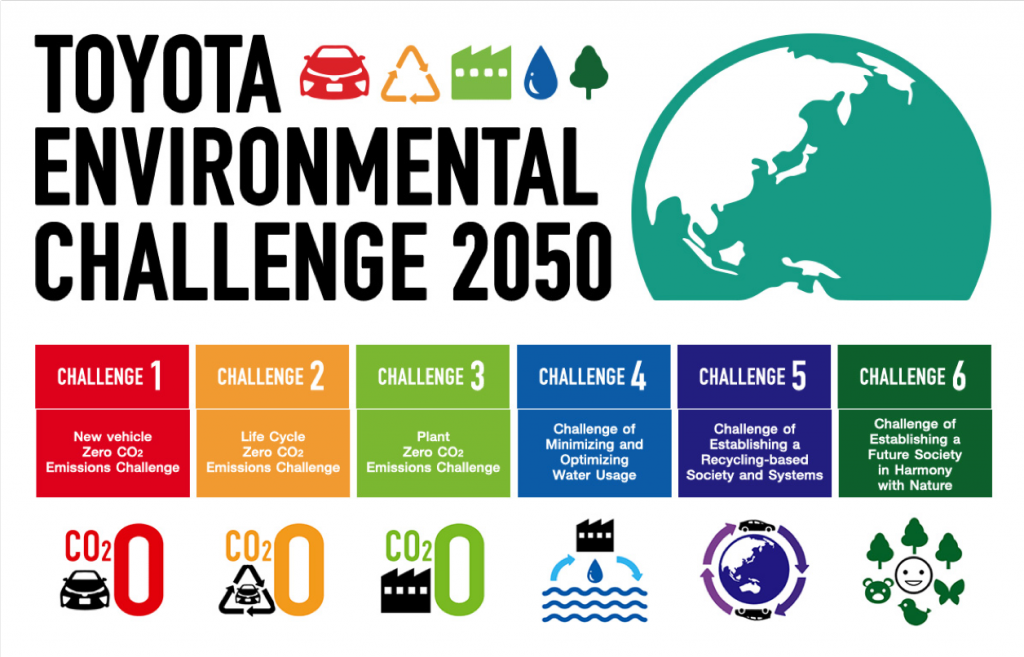

On a whole, manufacturers use a lot of energy that cause more and more CO2 emissions. Resulting in harmful effects on the environment, these emit even more greenhouse gases that pollute the air. So, what is Toyota’s plan to fight this? What they have done is start by setting a goal to reduce CO2 emissions by 35% in their worldwide plants by 2030. The next, and ultimately most important goal, is to completely eradicate CO2 emissions by 2050.

A main part of the Toyota Environmental Challenge 2050 is to actually reduce the carbon footprints of their factories, and not just in the individual cars they produce. As such, Toyota Global has set actions into motion to find solutions for recycling, alternative energy and slim lines.

Read more about Toyota’s Challenge number 3, the Plant Zero CO2 Emissions Challenge >

Simple and slim lines

Toyota is utterly committed to lean manufacturing principles though its Toyota Production System. The system is dedicated to innovation and evolving, as it has done for years. A major part of these simple lines comes in the form of Karakuri Kaizen. These are green and frugal robots, that need no electricity or external energy. Perfect for Toyota’s challenges!

At Toyota, they really value each worker’s quality-assessment capacities. This translated to an extremely developed skills that are very flexible and linked to kaizen. Kaizen are continuous improvements, the product of a worker’s imagination. They can use this to develop their own Karakuri Kaizen, which have become the centre of Toyota’s lean manufacturing strategy. Automation henceforth becomes inexpensive and flexible.

Small differences can make a big difference

Toyota resumes this as:

Realising eco-friendly vehicles that are made with nature and that run with nature. Exceeding expectations for the smiles of the future.

If everyone had the same mindset, and everyone says, “I can make a small difference and I’m going to”, then you end up with a big difference.

#MakeAMove