An introduction to cells

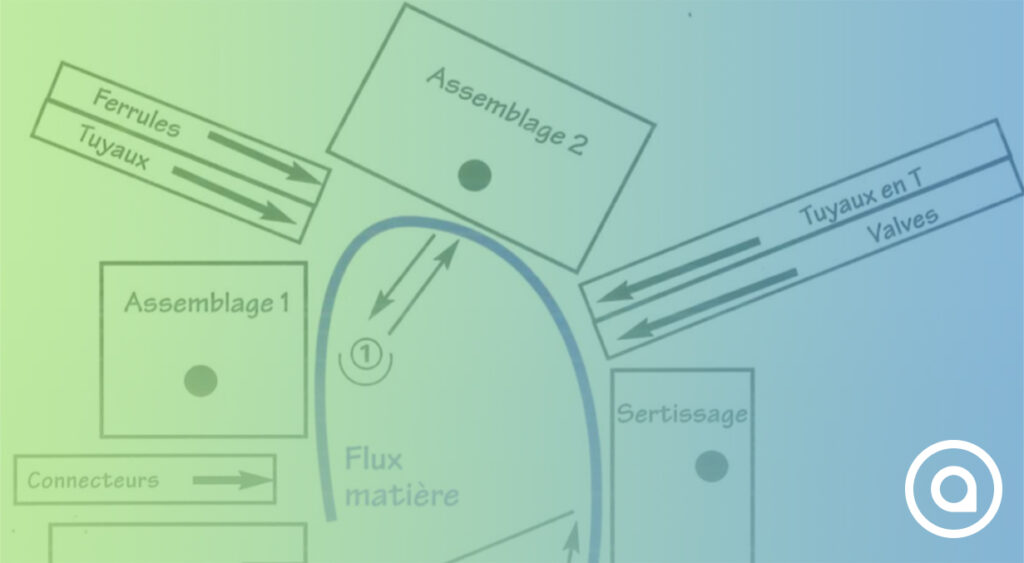

A cell refers to a specific type of place where the manufacturing of a product follows a workflow. In this workflow, the various processes are adjacent to each other. This allows for a continuous flow, either with one piece at a time or in small batches throughout the sequences of production.

U-shaped lines that make work easier and better

The most common form of these cells is in a U-shaped design. This proves to minimize traveling distances. In turn, it accommodates different combinations of tasks for the operators. From a lean production point of view, this feature is key because it makes it easier to adapt the number of operators in a cell according to variations in demand.

A U-shape also makes it easier for the same operator to perform the first and last task of a process, which helps to maintain a steady work rate and flow. Many companies actually use the terms “cell” and “line” in an interchangeable manner.

One way of doing things advocates that parts should move from right to left in the cell. This is because most people are right-handed, approximately 90% according to Wikipedia. Therefore, it would be more efficient and even more natural to work from right to left. However, many processes are arranged in the opposite way with the same level of efficiency. The most appropriate solution should hence be evaluated on a case-by-case basis.

Use-case / Before

The before situation:

- The walking distance from start to finish is too far. This causes time to be lost, idly.

- The inside of the cell is too large. Valuable footprint space is wasted.

- The starting point and the finishing point are too far apart. This causes a loss of time for the operator, who at the end of a cycle, has to walk back to his starting point.

- There are large free surfaces between the workstations. This favours the build-up of half-finished products.

- The tube bending machine needs to be modified to allow a one-by-one cycle.

- The exit tray of the bending machine impedes the worker as he walks.

Use-case / After

By reorganising the cell, the working space becomes something quite different to before. This set-up will be finetuned as it is put into place in the factory. Nevertheless, even with all of the improvements brought to the physical installation, one question remains. How should one incorporate the workers and their tasks into the brand-new configuration?

U-shaped cell design

Images by Lean Institute France